Oil, along with natural gas, has hundreds of different uses in a modern vehicle through petrochemicals. Today’s infographic comes to us from American Fuel & Petrochemicals Manufacturers, and covers why oil is a critical material in making the EV revolution possible.

Pliable Properties

It turns out the many everyday materials we rely on from synthetic rubber to plastics to lubricants all come from petrochemicals.

The use of various polymers and plastics has several advantages for manufacturers and consumers:

Today, plastics can make up to 50% of a vehicle’s volume but only 10% of its weight. These plastics can be as strong as steel, but light enough to save on fuel and still maintain structural integrity.

This was not always the case, as oil’s use has evolved and grown over time.

Not Your Granddaddy’s Caddy

Plastics were not always a critical material in auto manufacturing industry, but over time plastics such as polypropylene and polyurethane became indispensable in the production of cars.

Rolls Royce was one of the first car manufacturers to boast about the use of plastics in its car interior. Over time, plastics have evolved into a critical material for reducing the overall weight of vehicles, allowing for more power and conveniences.

Timeline:

1916 Rolls Royce uses phenol formaldehyde resin in its car interiors 1941 Henry Ford experiments with an “all-plastic” car 1960 About 20 lbs. of plastics is used in the average car 1970 Manufacturers begin using plastic for interior decorations 1980 Headlights, bumpers, fenders and tailgates become plastic 2000 Engineered polymers first appear in semi-structural parts of the vehicle Present The average car uses over 1000 plastic parts

Electric Dreams: Petrochemicals for EV Innovation

Plastics and other materials made using petrochemicals make vehicles more efficient by reducing a vehicle’s weight, and this comes at a very reasonable cost. For every 10% in weight reduction, the fuel economy of a car improves roughly 5% to 7%. EV’s need to achieve weight reductions because the battery packs that power them can weigh over 1000 lbs, requiring more power. Today, plastics and polymers are used for hundreds of individual parts in an electric vehicle.

Oil and the EV Future

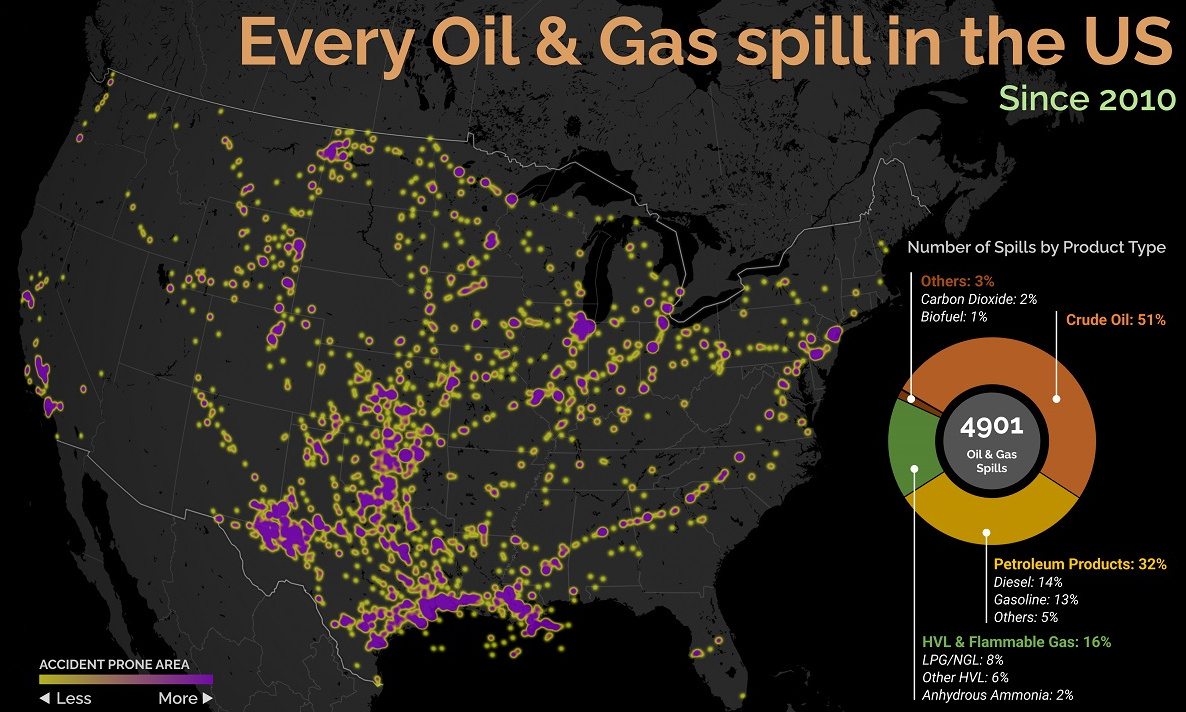

Oil is most known as a source of fuel, but petrochemicals also have many other useful physical properties. In fact, petrochemicals will play a critical role in the mass adoption of electric vehicles by reducing their weight and improving their ranges and efficiency. In According to IHS Chemical, the average car will use 775 lbs of plastic by 2020. Although it seems counterintuitive, petrochemicals derived from oil and natural gas make the major advancements by today’s EVs possible – and the continued use of petrochemicals will mean that both EVS and traditional vehicles will become even lighter, faster, and more efficient. on Aside from the obvious climate impact they bring, one other downside in particular is spills, which can lead to ecological and economic damage. These can happen due to pipeline leaks, train derailments, or other industrial disasters. This graphic from Preyash Shah provides a visual overview of every oil and gas spill in the contiguous U.S. since 2010. Data is tracked by the U.S. government’s Pipeline and Hazardous Materials Safety Administration (PHMSA).

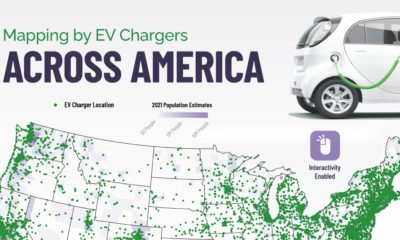

U.S. Oil and Gas Spills (2010‒2022)

The majority of spills that have occurred come mostly from crude oil, followed by petroleum products and gas. Note that this data covers the quantity of spills and not damages or volume.

Crude oil, which makes up just over half of documented spills, is also one of the most costly. Contaminations can persist for years after a spill, and its impact on local mammals and waterfowl is particularly harsh. This has been the case with the Deepwater Horizon spill (also known as the “BP oil spill”), which experts say is still causing harm in the Gulf of Mexico. Other products with lots of spills include petroleum products such as diesel or gasoline, as well as liquefied natural gas or other volatile liquids. Interestingly, liquefied carbon dioxide can also be transported in pipelines, commonly used for carbon capture storage, but requires high pressure to maintain its state. When looking at the location of spills, it’s clear that the South Central states have experienced the highest number of disasters. In contrast, the West Coast has had substantially less activity. However, this makes much more sense when looking at the dominant oil producing states, where Texas and surrounding neighbors reign supreme. Of the 4,901 spills during this period, Texas accounts for 1,936 or roughly 40% of all oil and gas spills. This is followed by Oklahoma, which has had 407 spills and is one of the largest net exporters of oil and gas in the country.

What Causes Spills?

Oil and gas spills actually have a surprisingly long history, with one of the earliest dating back to 1889, when a spill was reported on the coast between Los Angeles and San Diego. Causes have consisted primarily of weather, natural disasters, equipment and technological malfunction, as well as human error. However, they only became a widespread problem around the halfway mark of the 20th century, when petroleum extraction and production really began to take off. This era also saw the emergence of supertankers, which can transport half a million tons of oil but therefore make the risk of spills even costlier. In fact, the biggest spill off U.S. waters after the Deepwater Horizon disaster is the 1989 Exxon Valdez spill in Alaska, when a tanker crashed into a reef and 11 million gallons of oil spilled into the Pacific Ocean.